Views: 0 Author: Site Editor Publish Time: 2025-02-25 Origin: Site

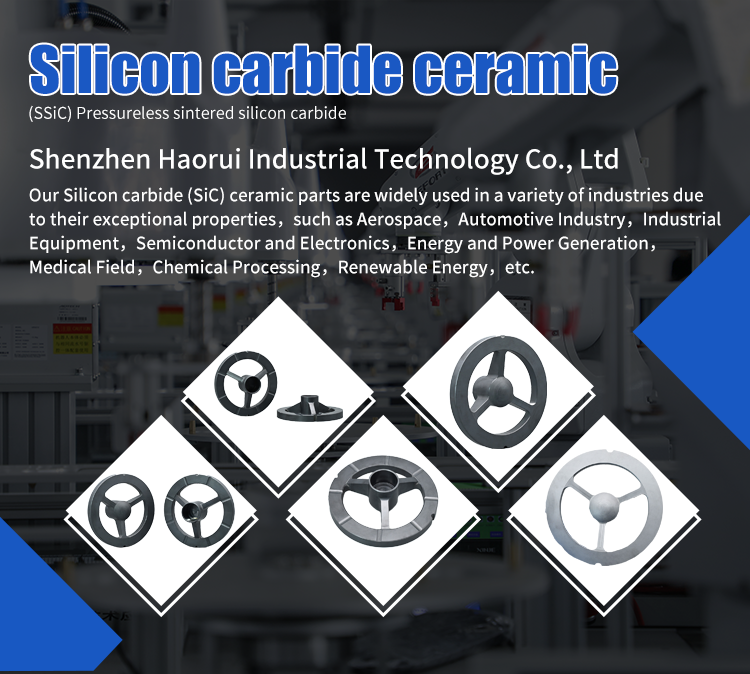

In industrial applications, sealing performance is crucial for ensuring efficiency, durability, and reliability. Silicon Carbide Ceramic Seal Rings are widely recognized for their exceptional mechanical strength, wear resistance, and corrosion resistance. As a leading manufacturer, Shenzhen Haorui Industrial Technology Co., Ltd. specializes in producing high-precision ceramic components, including advanced silicon carbide seals tailored for various industries.

Why Choose Silicon Carbide Ceramic Seal Rings?

Silicon carbide (SiC) is a highly durable material that offers superior properties compared to traditional sealing materials. Here are some key advantages:

Excellent Hardness & Wear Resistance: SiC is one of the hardest materials, ensuring long-lasting performance under extreme conditions.

Superior Corrosion Resistance: With excellent chemical stability, it resists acids, alkalis, and other corrosive substances.

High-Temperature Stability: Withstands temperatures up to 1600°C, making it ideal for high-heat environments.

Low Friction & High Thermal Conductivity: Reduces energy consumption and improves heat dissipation for enhanced operational efficiency.

Customization & Precision Engineering: Available in various sizes, shapes, and specifications to meet specific industrial needs.

In recent years, Silicon Carbide Ceramic Seal Rings have seen significant advancements in manufacturing technology, leading to enhanced durability and efficiency. Innovations in nanotechnology, advanced sintering processes, and precision machining have improved product performance, making them more adaptable to demanding industrial applications. Additionally, the growing emphasis on sustainability and energy efficiency has increased the demand for SiC-based seals in renewable energy, electric vehicles (EVs), and high-tech industries.

Looking ahead, the demand for Silicon Carbide Ceramic Seal Rings is expected to grow substantially in regions such as:

United States & Canada: Driven by the expansion of high-performance mechanical and aerospace industries.

Europe: Increasing demand in automotive, chemical processing, and renewable energy sectors.

China & India: Rapid industrialization and the rise of electric vehicles and power generation applications.

Southeast Asia & Middle East: Growing investments in oil & gas, water treatment, and high-tech manufacturing.

·

Due to their outstanding performance, Silicon Carbide Ceramic Seal Rings are widely used in industries such as:

Mechanical Seals: Used in pumps, compressors, and rotary equipment for leak prevention.

Automotive Industry: Essential for water pumps, turbochargers, and fuel systems.

Aerospace & Defense: Ensures durability in extreme environments.

Chemical Processing: Resists harsh chemicals in reactors and processing units.

Power Generation: Used in steam turbines and nuclear power applications.

As an expert in precision ceramic parts manufacturing, Shenzhen Haorui Industrial Technology Co., Ltd. integrates R&D, production, and sales to deliver high-quality silicon carbide components. With state-of-the-art production facilities, advanced processing technology, and strict quality control, we ensure top-tier performance for every product.

Cutting-Edge Manufacturing Technology: We utilize advanced CNC machining, grinding, and polishing techniques to achieve high precision.

Custom Design Solutions: We provide tailored solutions to meet diverse industrial demands.

Strict Quality Assurance: Our products undergo rigorous inspection to guarantee reliability and durability.

Global Supply & Competitive Pricing: Serving industries worldwide with cost-effective, high-performance ceramic seal rings.

For high-quality Silicon Carbide Ceramic Seal Rings, contact Shenzhen Haorui Industrial Technology Co., Ltd. today! We are committed to delivering precision, durability, and reliability for your industrial applications.

Website: https://www.heroceramic.com/

Email: sales@szhr-tech.com

Phone: +86-18681530447

Address: Shenzhen, China